Often we don’t think about all the different ways logos are going to be used when they are being created. Because of that, some adjustments may need to be made for different things. Embroidery is one of those things! Embroidery on hats is something else to consider altogether!!

When sewing a logo on, say, a polo, logos can be pretty tall and it isn’t a problem. There’s plenty of vertical space to work with on shirts. When sewing on hats you have a very limited space of about 2.25 inches. Anything bigger than that won’t work for a hat. Because of this some adjustments will need to be made to any vertical logo to make it fit where it needs to be.

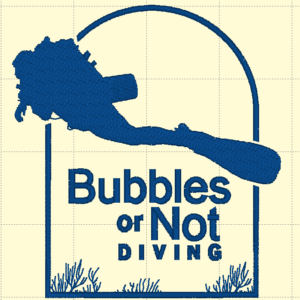

We can often accomplish this by using the main elements of your logo and just reworking it a bit. Bubbles or Not in Harlem GA has a logo that is a perfect example of this. Their standard logo is vertical, but when they wanted to get some hats made we needed to change a few things up to make it happen.

This is their standard logo. It works great on apparel! It does not, however, work great for hats. This version of their logo is over 3 inches tall.

How did we solve this problem? Glad you asked!! We took the diver and the text, reworked it a bit and just like that, we have a file that will work great for a hat!!